Powder Metallurgy Process

Application area

1. Mechanical and electrical industries, ultra-high voltage electrical contact materials and electrode materials

2. Electronic industries, such as substrates, connectors and radiators electronic packaging materials

3. Metallurgical industries, such as precision rolling mills, elliptical pass guides, etc

4. Military and aerospace industries, such as armor-piercing projectiles, electromagnetic gun rail materials and rocket engine nozzles, nose cones, etc.

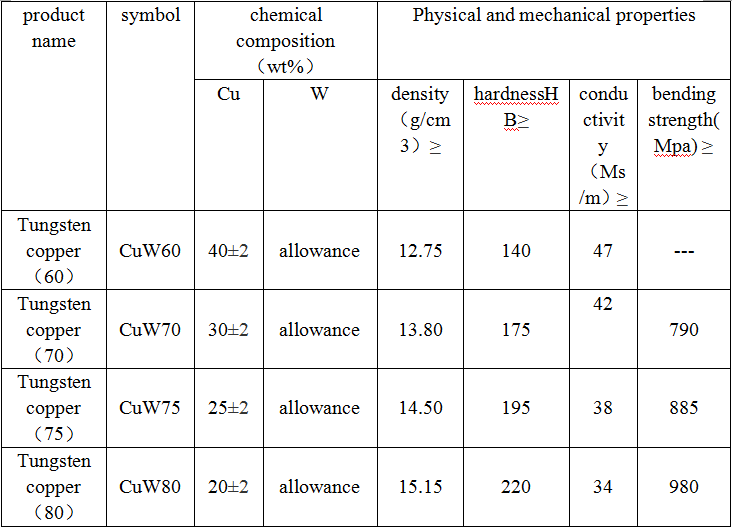

Technical Parameters

Production Process

The production methods of tungsten and copper composites can be divided into four kinds: mixing and pressing sintering method, infiltration method, activation sintering method, nano\ ultrafine mixed powder sintering method.

At present, the main method of preparing tungsten and copper materials is infiltration method. The advantages of this method are that the composition of the materials is more uniform, the density is high, the impurities are less, and the comprehensive properties are good. The theory of this method is to make tungsten skeleton with certain density and strength, and then infiltrated low melting point copper, a dense composite was formed by filling copper into the tungsten skeleton by capillary action.